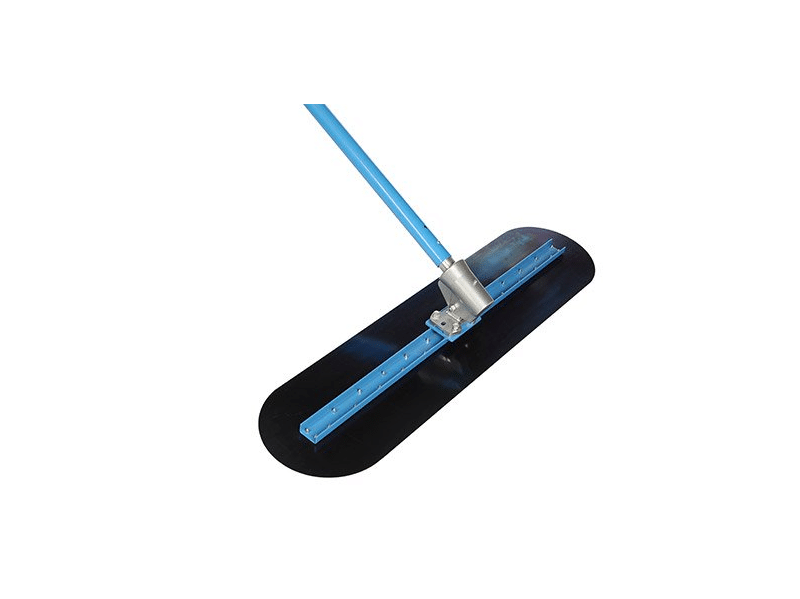

Achieve a perfectly smooth finish on your concrete with our float and bull float hire in Norfolk. Often called an easy float or concrete glider, this tool is essential for levelling freshly poured concrete slabs, driveways, and workshop floors. It eliminates imperfections and brings the fine ‘cream’ to the surface, creating a durable, professional-looking finish ready for trowelling or brushing. Our lightweight, long-reach floats save you significant time and effort compared to using hand trowels alone. For reliable concrete finishing tool hire across Breckland and Norfolk, contact Breckland Plant Hire today.

£35.00 – £100.00Price range: £35.00 through £100.00

Pouring a concrete slab is a job of precision and timing. Once the concrete is poured and tamped, you have a limited window to transform a rough, aggregate-heavy surface into a smooth, flat, and durable finish. This is the stage where true professionals stand out, and the key to their success is a tool often known as a Bull Float, Easy Float, or, as some in the trade call it, a Concrete Glider.

At Breckland Plant Hire, we supply contractors and DIY specialists across Norfolk with the essential finishing tools needed for a flawless result. Attempting to finish a large slab with just a hand trowel is a recipe for a sore back and an uneven, unprofessional surface. Hiring a long-reach bull float is the only way to achieve consistent, high-quality results efficiently.

A bull float is a simple but highly effective tool consisting of a long, lightweight, multi-section pole handle connected to a wide, flat blade (the float head). These blades are typically made from magnesium or aluminium.

Its purpose is twofold:

Without this crucial step, the surface remains rough and open-pored, leading to a weaker finish that can flake and spall over time.

A bull float is a specialist tool. For anyone not laying large amounts of concrete every single day, hiring is the most logical and cost-effective option.

Using a bull float is a skill, but the basic technique can be mastered quickly. The most critical factor is timing.

Whether you are pouring a large agricultural floor near Swaffham, a new driveway in Dereham, or a perfect workshop base in Thetford, Breckland Plant Hire has the equipment you need. We understand the demands of working with concrete and provide reliable, clean, and effective tools to match.

Our team can advise on the right tools for your specific project, from the initial groundworks with a compactor plate, to mixing with our reliable cement mixers, right through to the final touch with a bull float. Our delivery service across Breckland and the wider Norfolk area ensures you get the right tools on-site, right when you need them.

Don’t let poor finishing undermine your hard work.

To ensure your concrete project has a durable and professional finish, contact Breckland Plant Hire today to hire your bull float.